Termica Neo

Thermal Simulation of Chemical Reactions on an Industrial Scale

News

February 26,2024. New Termica Neo version 1.1.0 is released. The version has several new features important for high temperature simulations: using of thermal radiation, different physical properties for the reacting material and for the product and others. Details are in Release History.

January 30, 2024. New Termica Neo version 1.0.2 is released. This version is minor release with several improvements and bug fixes. Details are in Release History.

January 17, 2024. First version of NETZSCH Termica Neo is released: version 1.0.0.

November 21, 2023. Webinar Termica Neo: The New NETZSCH Software for Thermal Simulation on an Industrial Scale

Dr. Elena Moukhina showed new NETZSCH Termica Neo software for both the simulation of industrial processes such as curing or polymer crystallization where the temperature gradients in the reacting media have an influence on product quality, and for highly exothermal materials where temperature gradients impact the safety conditions of runaway reactions.

What Is Termica Neo?

Termica Neo is software for the simulation of thermal behavior and thermal safety for chemical reactions and crystallization in solids or liquids, in volumes with linear sizes from centimeters to meters. The main applications are materials with high thermal potential, as well as reactions of curing, cross-linking, sintering and polymer crystallization.

Termica Neo can:

- Simulate your material's behavior at each point inside the container.

- Determine the location and timing of the maximum temperature or maximum conversion rate of the reactant inside the container.

- Determine the temperature, conversion, and concentrations of the reactant for a given time and position inside the container.

- Predict your degree of curing, decomposition, and crystallization.

- Determine thermal safety conditions for production and storage.

Curing in a Cylindrical Container

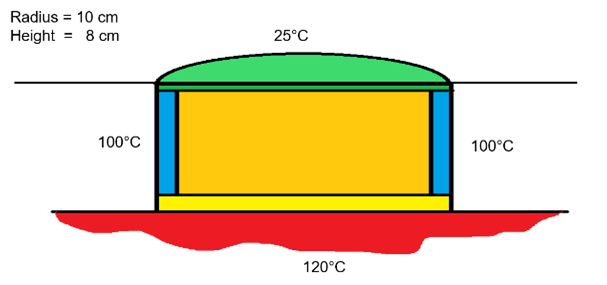

Curing of epoxy in cylindrical aluminum container of different thicknesses (from 0.3 to 1 cm) with different temperature conditions on each surface. Bottom temperature is 120°C, side temperature is 100°C, top temperature is 25°C. We can find out if the material is cured completely everywhere in this volume after a waiting time of 130 min.

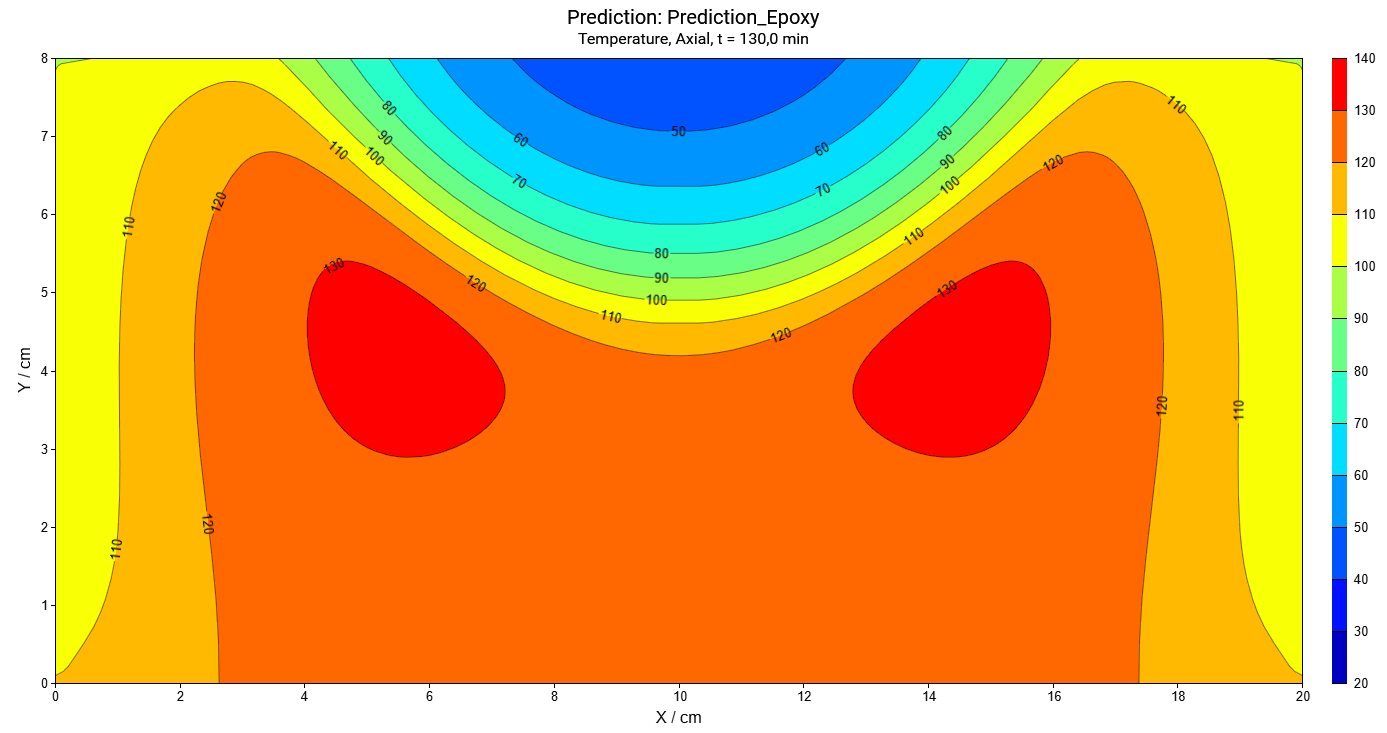

Simulation results: Temperature distribution for the vertical cross-section at a time of 130 min.

The bottom part and the middle part of the volume are already warm, but the central part of the top of the cylinder is still cold. Red areas on the temperature plot signify hot spots due to self-heating. In the cylinder the hot circle is positioned at a height of 4 cm and at a distance of 6 cm from the side.

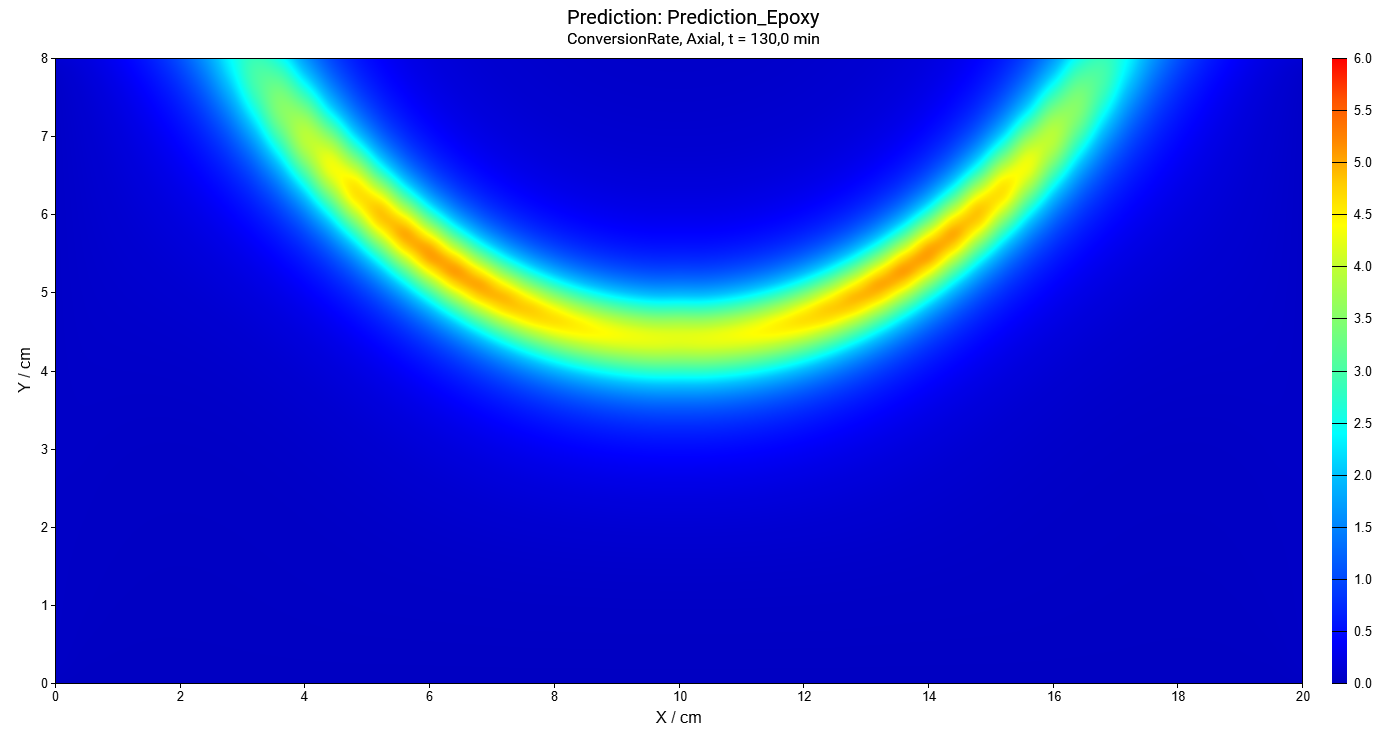

Simulation results: Conversion rate distribution for the vertical cross-section at a time of 130 min.

This figure presents the round front of the reaction which moves from the warm bottom surface to the cold top surface. The red areas means the highest reaction rate. The blue area below the reaction front means already cured material, where the reaction is already finished. The blue area above the reaction front means the material, which is not yet cured.

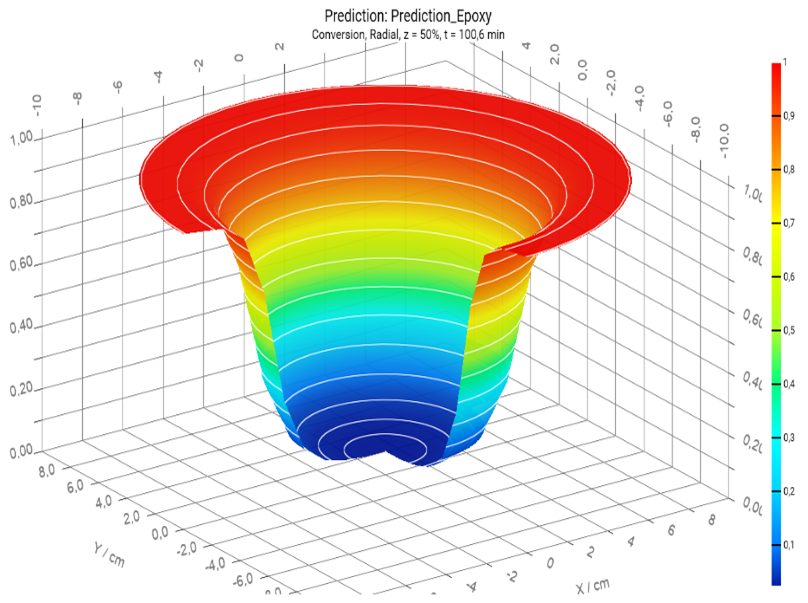

Simulation results: Degree of conversion for the horizontal cross-section at 50% of sample height and a time of 100 min.

The blue part in the middle signifies a low degree of cure near the vertical axis. The red parts with the maximum radius signifies complete curing near the side surface.

The software offers the ability to see the cross-section at any user-selected vertical position within the cylinder.

Self-Acceleration Decomposition Temperature (SADT)

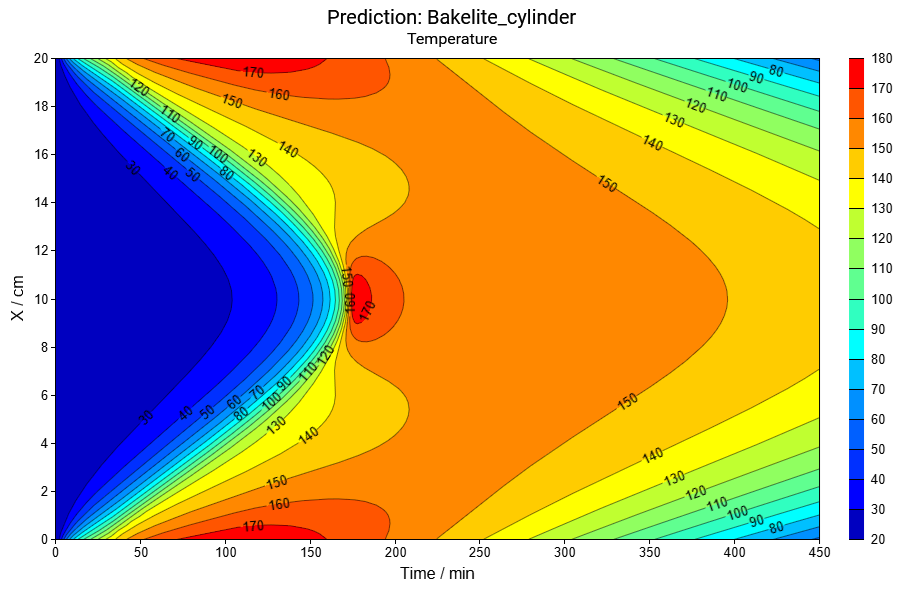

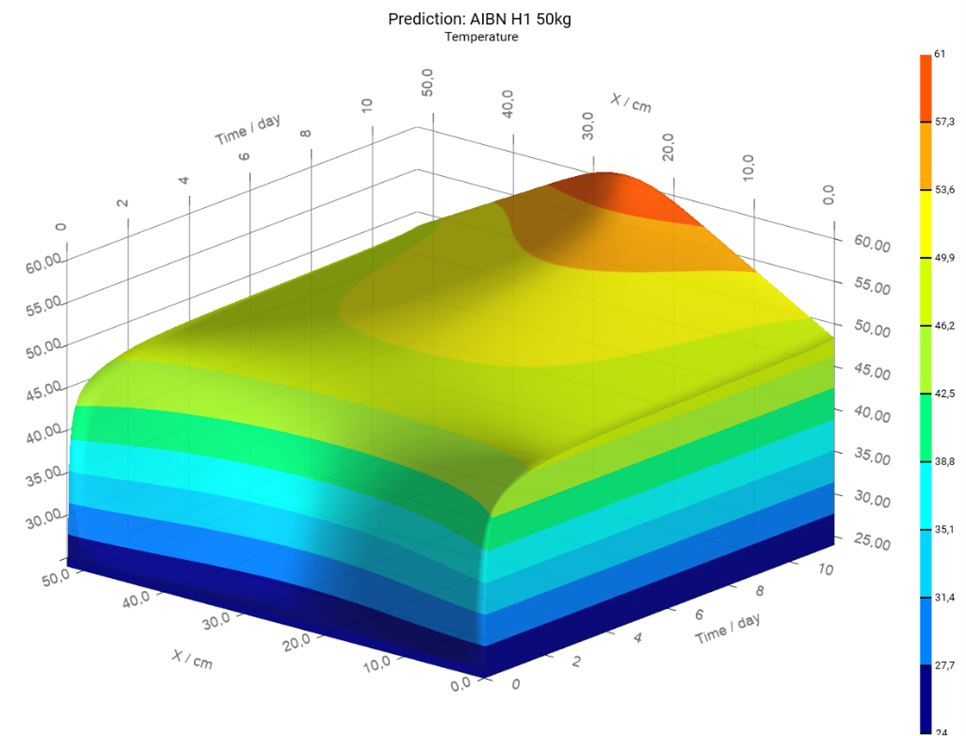

Temperature (x,t) for decomposition of the package of 50 kg of AIBN.

The spherical package with a diameter of 50 cm has an initial temperature of 25°C and is placed into storage in air at a temperature of 48°C.

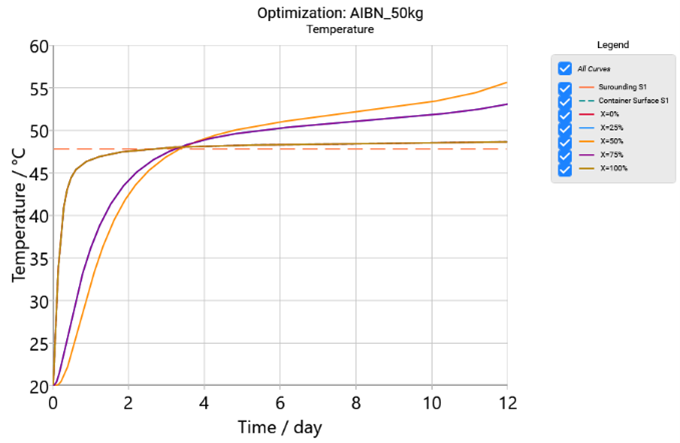

SADT calculation for the decomposition of the package of 50 kg of AIBN.

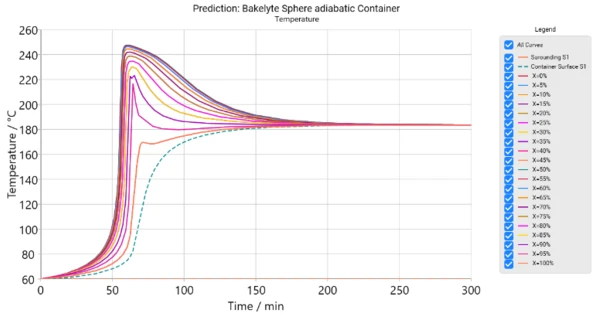

Reactant in Adiabatic Container

Simulation of the temperature distribution of an adiabatic system: reactant (solid lines) in a container (dashed line).

The final temperature corresponds to the classical results calculated by using the Phi-factor.

What Makes Termica Neo So Valuable

- Fast and easy-to-handle user interface similar to Kinetics Neo.

- The kinetic modes are taken directly from the Kinetics Neo project (results of any method including both model-based and model-free).

- Calculation of the following properties at each point of volume as a function of time:

- temperature,

- conversion,

- conversion rate,

- concentrations,

- glass transition temperature.

- Calculation of Self-Accelerating Decomposition Temperature (SADT) using various materials, containers and surroundings.

- Simulation of reactions for a reactor with container, including adiabatic conditions.

System Requirements

Termica Neo runs under Microsoft Windows 11 64-bit or Windows 10 64-bit version.

NETZSCH Kinetics Neo software version 2.5 or later is required.

Minimum hardware requirements are: Intel® Core i5 processor of 11 generation (Core i5 11400) or later, 16GB RAM, DirectX 11 compatible graphics, display 1440x1050.

Recommended hardware requirements are: Intel® Core i7 processor of 11 generation or later, 24 GB RAM, graphics nVidia 1080 GTX or better, display 1920x1200.